Organic Rankine cycle generator ORC system

Green energy equipment

ORC systems can be used to produce electricity and heat. Fuels suitable for ORC power generation include new energy (biomass, geothermal, solar, industrial waste heat), traditional fuels and waste heat from industrial processes, waste incinerators, engines or gas turbines.

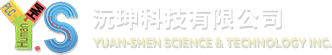

The working principle of the organic Rankine cycle is different from that of general geothermal steam turbines. The ORC process uses geothermal fluid with low to high enthalpy to preheat and evaporate the appropriate organic working fluid in a closed cycle.

The organic working fluid vapor drives the rotation of the turbine, which is directly coupled to the generator. The exhaust steam flows through the reheater and condenser and is cooled by air or water.

The organic working fluid is pumped back into the reheater, completing the closed cycle. In this way, the ORC turbine is not in contact with the geothermal fluid, the fluid is always in the heat exchanger, and both the brine and steam condensate can be completely returned and will not be discharged to the environment.

ORC system design

It can convert small-scale commercial or large-scale industrial waste heat sources into practical-grade pollution-free electricity. The planning scope ranges from 150KW to 20MW to select equipment and build systems. It can mainly convert the thermal energy of hot water and hydrothermal liquid above 90℃ or flue gas above 150℃ into electrical energy. In this process, no additional fuel is consumed and no new emissions are produced. Achieve double benefits of economy and environmental protection.

At present, the total installed capacity of the products actually used worldwide exceeds 20MW, and the operation stability is very reliable. It is suitable for different heat sources and various application environments, such as: industrial waste heat, geothermal heat, solar heat, biomass energy, waste incineration, spent fuel utilization, compressor interstage cooling, etc.

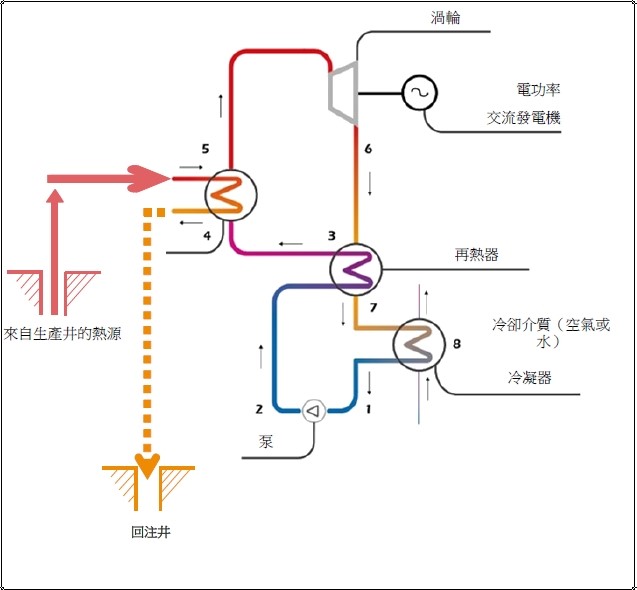

The basis of ORC technology is to use heat source (high pressure) and cold source (low pressure) to drive airflow to generate electricity. Each module consists of an evaporator that transfers heat to the internal working fluid, a turbine generator that converts heat energy into electrical energy, and a cooling system that transfers heat from the module to a cooling water circuit.

Thermal energy from the heat source boils the internal working fluid in the heat exchanger. The vaporized working fluid flows through the turbine, turning a generator to generate electricity. The fluid then enters the condenser tank where the gas is in direct contact with the cooled working fluid. Then, the liquid working fluid is distributed to the cold and heat exchangers and heat exchangers through the pump, closing the loop.

The ORC organic Rankine cycle generator system will plan the appropriate model and system based on the customer's heat source.

-YSHR150 standard model: uses heat source above 90℃, rated output power 150KW, full power generation efficiency 6%~14%.

- Net power generation rate can reach 90% - after deducting self-sufficient electricity consumption

The entire process of organic working fluid is completely sealed and has no contact with the outside world. Will not leak.

- High-speed permanent magnet generator with an efficiency of over 98%, and the power output changes according to working conditions.

- The turbine generator rotor speed is 26500r/min.

- The unit operates stably, has a long service life and requires no maintenance.

- The main components are integrated on the frame, weighing only 2946kg, easy to install and occupying a small area.

- Simple grid connection, excellent grid connection interface: The power electronics automatically match the grid voltage and frequency, making it easier to sell electricity online or supplement local electricity.

- Suitable for commercial users in small-volume environments. The required hot water volume is at least 120m3/H. It is suitable for use in heat source environments above 90℃.

For clients below 1MW.

The user's heat source assessment can reach more than 1MW, and it will be recommended to plan large-scale ORC units and customize the design to improve power generation efficiency.

沅珅科技致力於儀電工程與自動控制儀表銷售 配合客戶需求與系統整合,提供最新資訊及服務