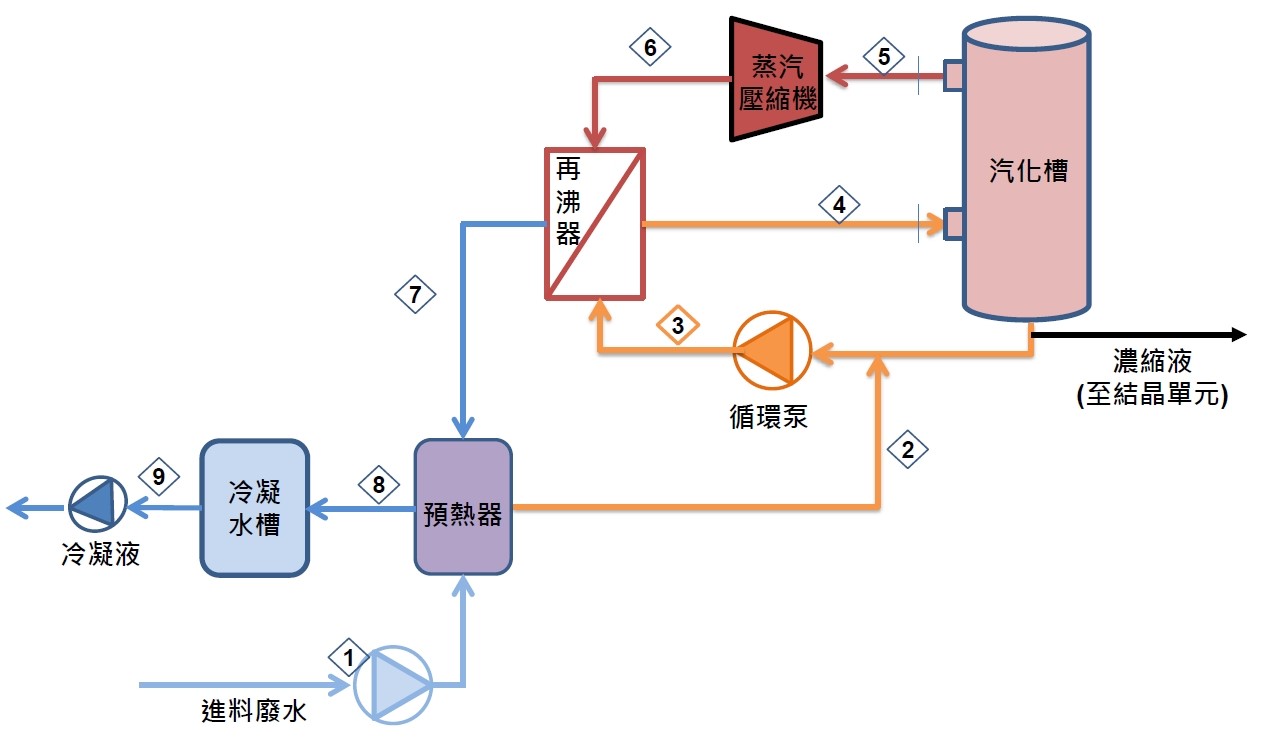

MVR mechanical vapor recompression system

Green energy equipment

MVR is the abbreviation of mechanical bapor recompression technology. MVR is an energy-saving technology that reuses the energy of the secondary steam it generates, thereby reducing the demand for external energy. As early as the 1960s, Germany and France had successfully used this technology in chemical industry, food, papermaking, medicine, seawater desalination and sewage treatment and other fields. The working process of the evaporator is to compress the low-temperature steam through the compressor, increase the temperature and pressure, and increase the heat enthalpy, and then enter the heat exchanger for condensation to fully utilize the latent heat of the steam. Except for startup, there is no need to generate steam during the entire evaporation process.

System process

instructions

*System Features

- Low operating cost, more than 80% energy saving compared to traditional evaporation

- Continuous operation, PLC automatic control

- Modular design, small footprint

- No initial steam required, simple public needs

*system applications

- High-concentration wastewater concentration targets ammonia nitrogen, nitrate nitrogen, boron and heavy metals and other indicators

- High-concentration waste liquid crystallization reduces outsourced removal costs

- Solvent wastewater recovery, such as ammonia nitrogen and IPA and other solvent wastewater

- Zero liquid discharge main unit

- Energy-saving transformation of evaporation distillation system

- Concentration and regeneration of production processes

*Features

- The compressor adopts a high-efficiency permanent magnet motor, which can reduce a lot of energy consumption by running continuously for a long time

- Fully automatic PLC and graphic control system operation, can plan and continuously record production and operation reports

沅珅科技致力於儀電工程與自動控制儀表銷售 配合客戶需求與系統整合,提供最新資訊及服務